China eusta technology co., ltd

EMI/EMC Honeycomb Shielding Vent/Waveguide

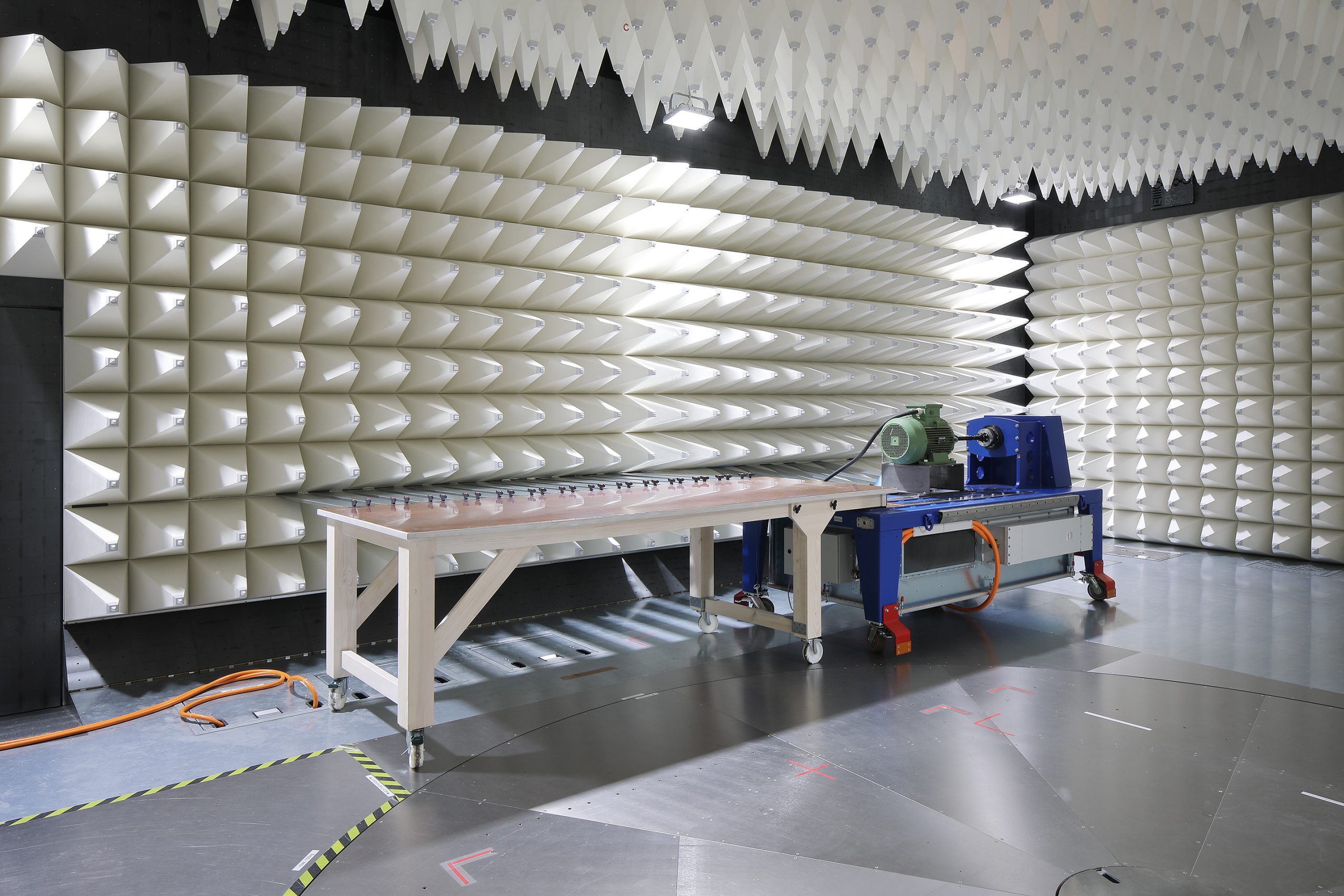

Honeycomb Shielding Vent/Waveguide designs with high shielding effectiveness, which is widely used in military chases, military shelter, microwave darkroom, computer reinforce, low radiate communicate equipment, medical device and test equipment. It has the maximum shielding effectiveness in both electric field and magnetic field and also meets the requirements of radiating.

The honeycomb shielding vent/waveguide delivers EMC, EMI and thermal management performance that meets the technology demands of today’s electronic systems, including:

- RF Shielding Room

- Module RF Shielding Room

- Welding RF Shielding Room

- RF Shielding Cabinet

- Computer Cabinet

- Radio Frequency Instrument

- High speed routers

- Indoor cellular base stations

- Network Servers

The honeycomb shielding vent/waveguide provides the same high performance as traditional honeycomb vent panels. Their honeycomb is 95% open area, minimizing pressure drop. The aperture size and cell depth provide the waveguide absorption and cut-off frequencies needed to solve even the most difficult EMI and airflow challenges.

We can make these vent/waveguide according to your drawing within a few days, or you can use our standard range from stock. If high shielding levels are required, the use of cross-cell honeycombs is recommended. These are constructed from multiple sections of 6.35 mm or 12.7 mm or 26.3 mm thick honeycombs within a single frame. The shielding performance will improve as air flow is decreased, but not eliminated.

Options:

- Cross-cell honeycomb for extra high shielding performance

- Slant honeycomb 30°, 45°, 60° for outdoor rainproof applications

- Stainless steel, mild steel or brass material

- Cell sizes 1.6 mm, 3.2 mm, 6.4 mm, 9.5 mm, 12.7 mm, or bigger (standard 3.2 mm)

- Gaskets for firm connections

*: Approximately 95% of the honeycomb vents we produce are made to customer specifications.

Cell Size:

D0.8mm—D30mm

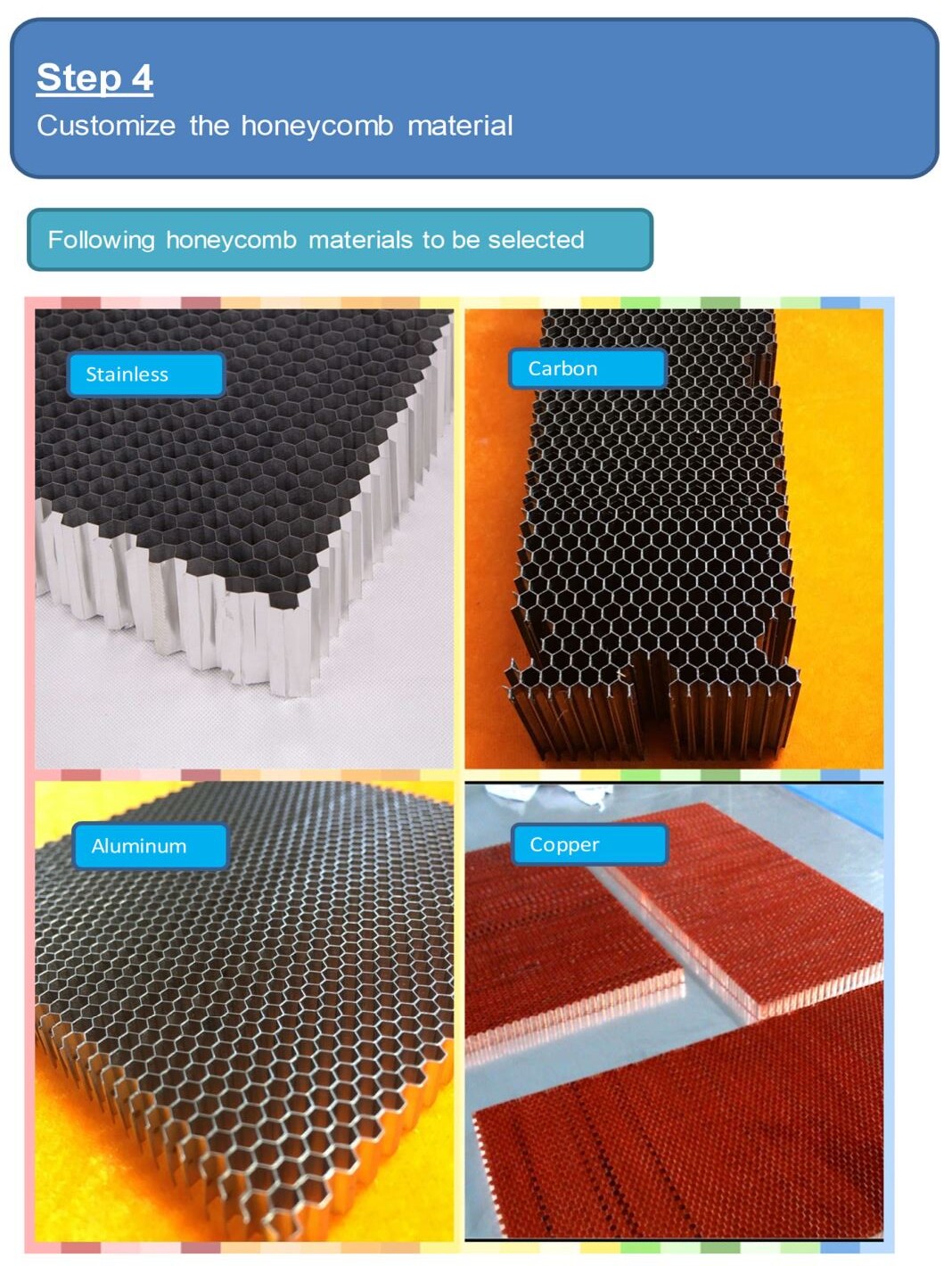

Material:

- Aluminum

- Carbon Steel

- Stainless Steel

- Brass/Copper

- Hastelloy X

Finishing:

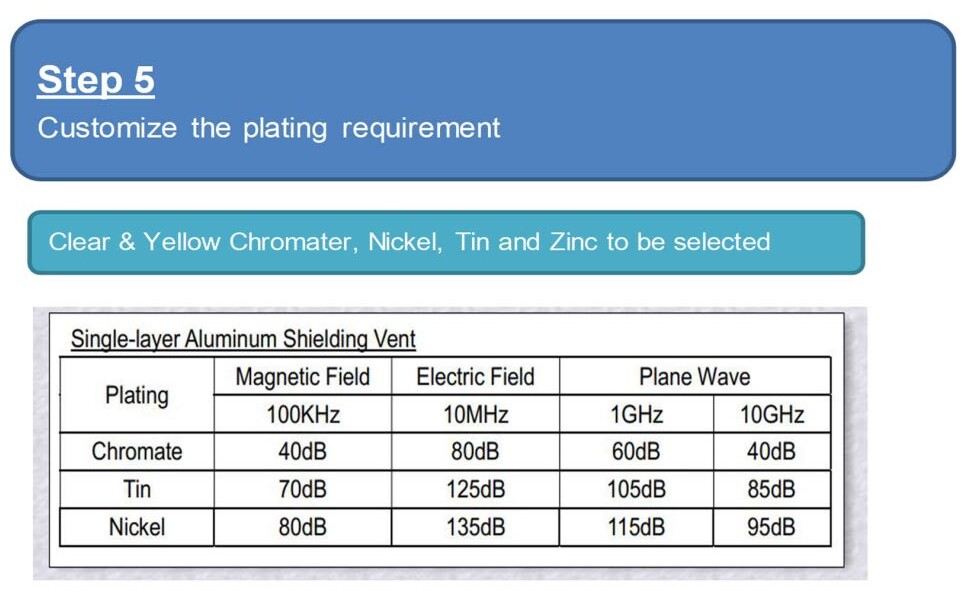

- Clear Chromate

- Yellow Chromate

- Tin

- Nickel

- Zinc

Honeycomb Shielding Vent

Manufacturing Flow Chart

Advanced and mature production and processing technology

Application

widely used in military chases, military shelter, microwave darkroom, computer reinforce, low radiate communicate equipment, medical device and test equipment.

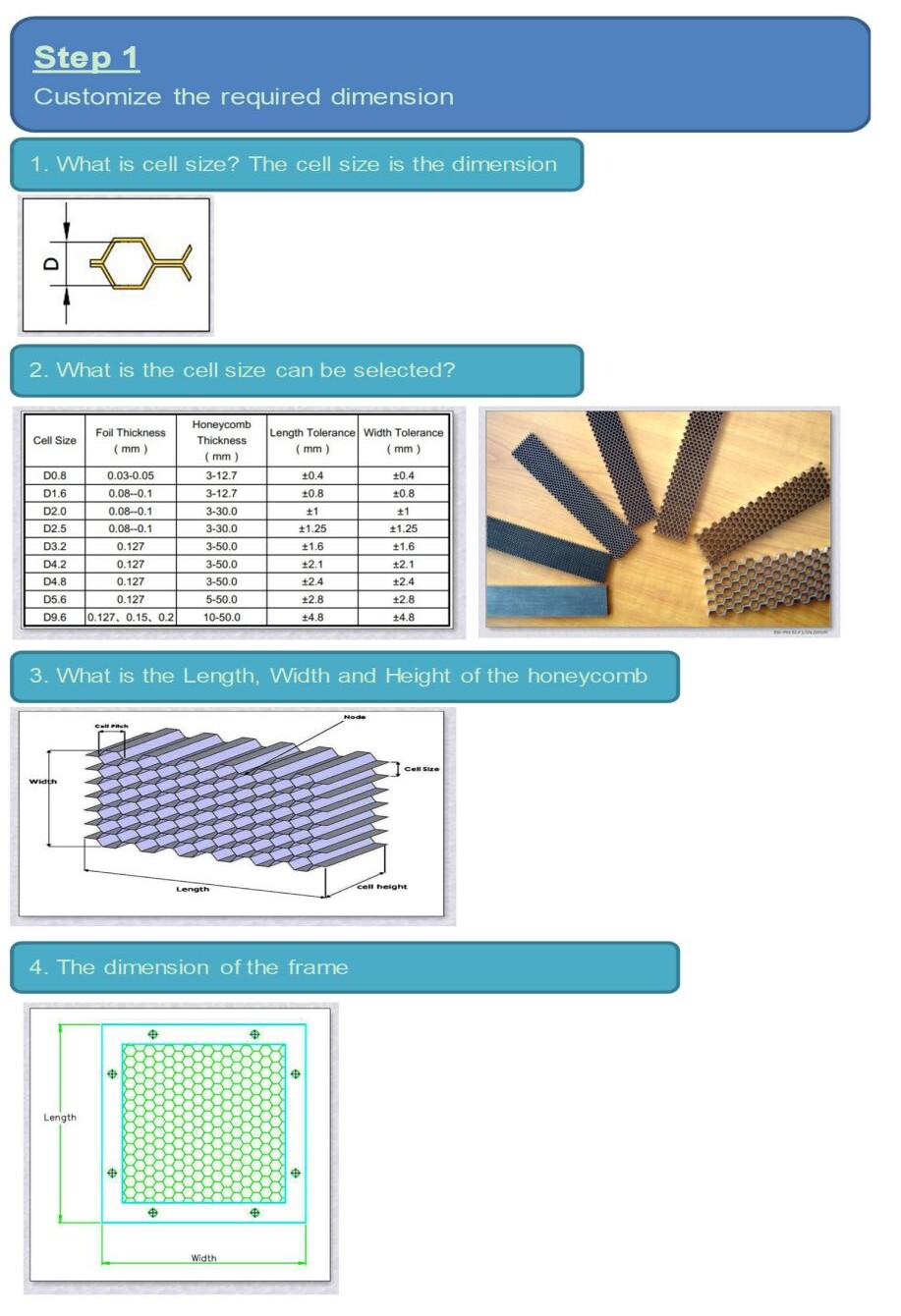

How to get price faster

Step one:

Customize the required dimension

1)What is cell size?

2) What cell size can be selected?

3) What is the Length, Width and Height of the honeycomb core?

4) The dimension of the frame.

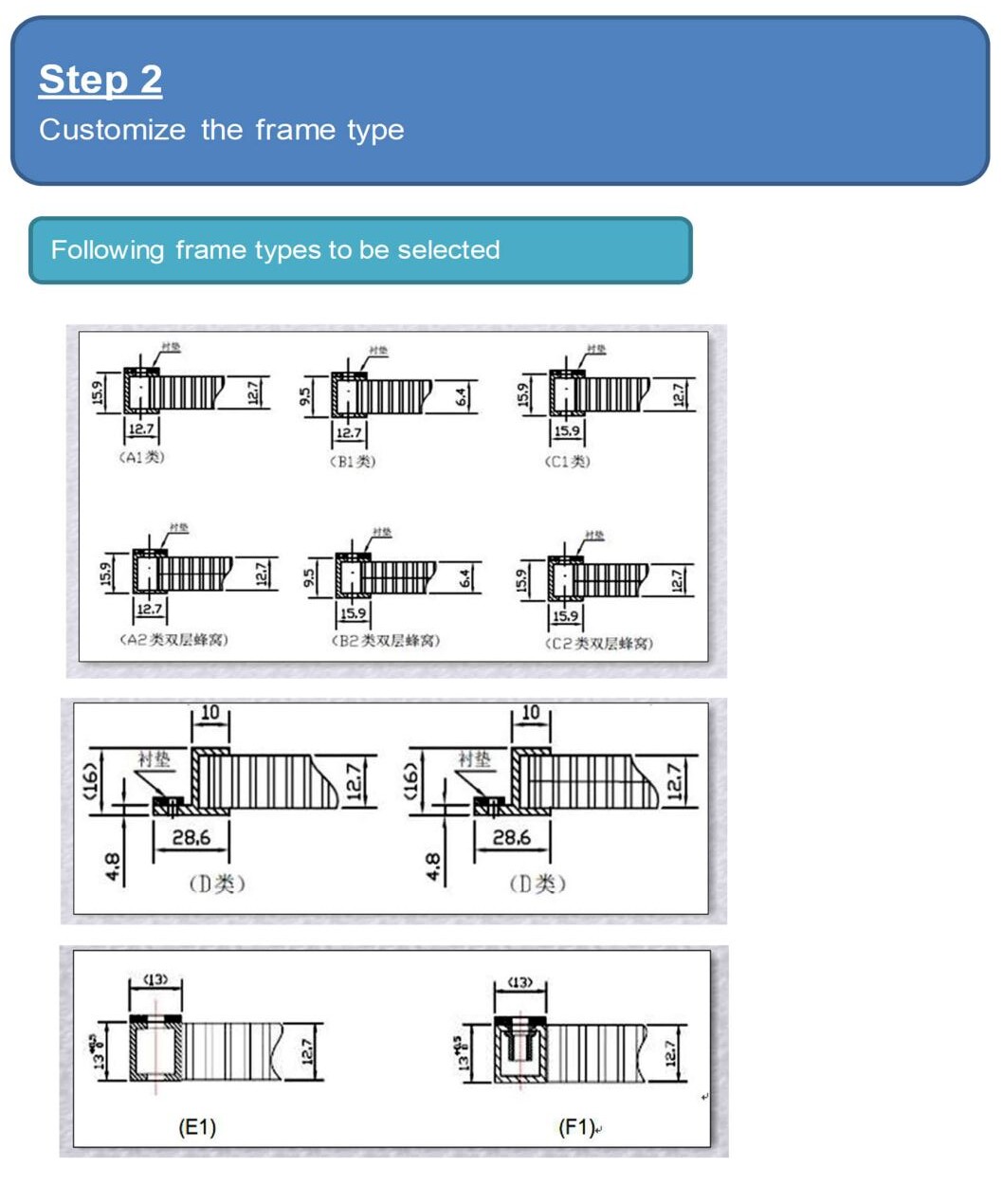

How to get price faster

Step two:

Customize the frame type

How to get price faster

Step three:

Customize the frame material

How to get price faster

Step four:

Customize the honeycomb material

How to get price faster

Step five:

Customize the plating requirement

How to get price faster

Step six:

Customize the gasket requirements

.jpg)

.jpg)

.jpg)

.jpg)